Fluidization of latent heat storage material (h-MEPCM) that can efficiently store medium-temperature waste heat - Clarification of thermal behavior and physical properties of the particles during fast heat storage and release -

Fluidization of latent heat storage material (h-MEPCM) that can efficiently store medium-temperature waste heat

- Clarification of thermal behavior and physical properties of the particles during fast heat storage and release -

Tokyo University of Agriculture and Technology group: Masahiro I. Aoki (Ph.D. student, Graduate School Graduate School of Bio-Applications and Systems Engineering), Takuto Aoki (Master's Course student, Graduate School of Engineering), Naoya Shirota (Former Master's Course student, Graduate School), and Professor Chihiro Fushimi (Division of Applied Chemistry, Institute of Engineering), and Hokkaido University group: Tomokazu Nakamura, (Academic Research Fellow, Graduate School of Energy and Materials Convergence Research Center), Dr. Melbert Jeem (Assistant Professor, Institute of Engineering) and Professor Takahiro Nomura (Institute of Engineering) experimentally clarified the behavior of fast heat storage and heat release behavior when latent heat storage material (h-MEPCM) is fluidized in the medium temperature region of approximately 100-300°C, and the changes in the physical properties of the particles before and after the fluidization. This research will make it possible to store and release heat approximately 100-300°C at a faster rate than before, which is expected to lead to further effective use of medium-temperature waste heat and mitigation of fluctuations in supply and demand at power plants in the future.

The results of this research have been published in the American Chemical Society's Energy & Fuels journal (December 4, 2025).

Paper title: Thermal and Physical Properties of Sn@α-Al2O3 Microencapsulated Phase Change Material (MEPCM) in a Fluidized Bed

Authors: Masahiro I. Aoki, Takuto Aoki, Naoya Shirota, Tomokazu Nakamura, Melbert Jeem, Takahiro Nomura, Chihiro Fushimi

URL: https://pubs.acs.org/doi/10.1021/acs.energyfuels.5c03913

DOI: 10.1021/acs.energyfuels.5c03913

Background

About half of the energy consumed in the world is lost as waste heat, of which more than 89% is concentrated at 100–300°C. Therefore, thermal energy storage for waste heat recovery is attracting attention. Latent heat storage that, uses energy absorbed and released during phase changes (Note 1) of materials, is attracting attention because it can release heat at a constant temperature and has a high energy storage density. Until now, Hokkaido University group has developed a latent heat storage microcapsule h-MEPCM (Hokkaido univ. Micro-Encapsulated Phase Change Material) that can be tuned up to the operating temperature at room temperature to 800°C and can be handled as ceramic particles, and has been shown to have high thermal conductivity and operability. However, in previous research, there were issues of latent heat storage materials that (1) the rates of heat storage and release were slow when a conventional fixed bed was used and (2) research on the heat storage and release of MEPCM particles in a fluidized bed (Note 2) has been limited to below 100°C. The lack of fluidized bed latent heat storage technology exceeding 100°C has been an issue for practical application.

Research Structure

This research was conducted by Masahiro I. Aoki of the Department of Food and Energy Systems Science of the Graduate School of Biological Applied Systems Sciences, Takuto Aoki, Naoya Shirota (at the time) of Department of Applied Physics and Chemical Engineering, Professor Chihiro Fushimi of the Graduate School of Institute of Engineering Division of Applied Chemistry at Tokyo University of Agriculture and Technology, Academic Research Fellow Tomokazu Nakamura, Assistant Professor Melbert Jeem, and Professor Takahiro Nomura of the Energy and Materials Convergence Research Center at Hokkaido University. The research was supported by the Grants-in-Aid for Scientific Research C(JP22K04815) of Japan Society for the Promotion of Science (JSPS), the Tanigawa Thermal Technology Promotion Fund (FY 2024), the Reiwa Environmental Foundation (FY 2024), and Next Generation Researchers Challenging Research Program (Spring) FLOuRISH Fellowship (JPMJSP2116) of the Japan Science and Technology Agency (JST).

Research Results

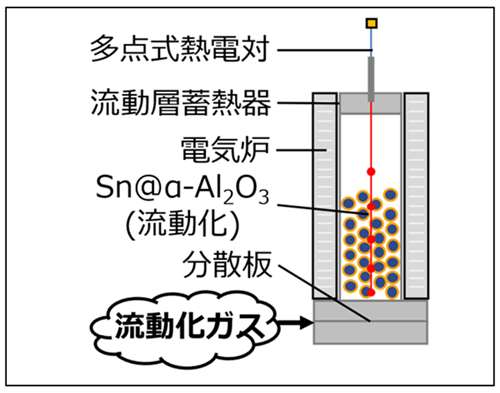

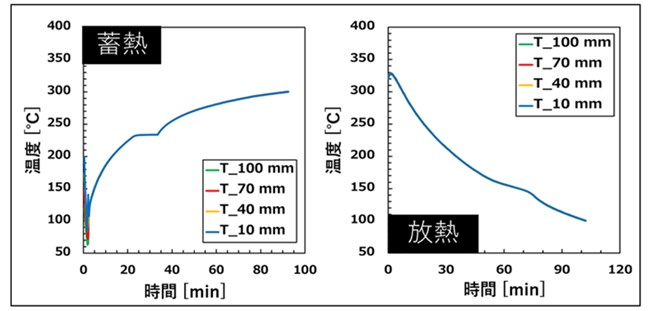

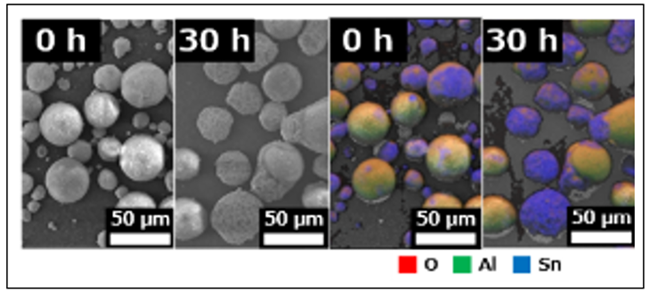

Hokkaido University group has developed the MEPCM particles (Sn@α-Al2O3)using tin as a phase change material and α-alumina particles as a capsule material to prevent it from melting in liquids, average particle size 31 μm, melting point 239 °C. Tokyo University of Agriculture and Technology group has conducted experiments, about the heat storage and release experiment using a fluidized bed at approximately 100-300 °C and clarified the details of the particles and their heat storage performance when fluidized for up to 40 hours.

Future developments

It is now possible to store and release medium-temperature waste heat (around 100-300°C) more quickly than before, and it is expected that the effective use of medium-temperature waste heat will be further expanded. In addition, by integrating it with biomass power plants, geothermal power plants, and thermal power plants, it is possible to store waste heat and surplus electricity and release it during times of power shortage, which is expected to help alleviate fluctuations in supply and demand at power plants.

Glossary

Note 1) Phase change

The change between solid, liquid, and gas phases. Usually, there is a large amount of heat in and out. Here, we make effective use of the heat in and out that accompanies the change between solid and liquid phases.

Note 2) Fluidized bed

This refers to equipment in which solid particles are suspended and fluidized like a liquid by injecting a fluid such as gas or liquid from below them in a vessel. Compared to a fixed bed, that does not fluidize the solid particles, this method has the advantage of promoting mixing of the solid particles within the device, thereby significantly accelerating the heat and mass transfer. However, fluidization can damage the particles.

◆Inquiries about research◆

Tokyo University of Agriculture and Technology

Institute of Engineering, Division of Applied Chemistry

Professor Chihiro Fushimi

TEL:+81-042-388-7062

E-mail: cfushimi (please put @ here) cc.tuat.ac.jp

◆Inquiries about the press◆

Tokyo University of Agriculture and Technology, Public Relations Office

E-mail:koho2 (please put @ here) cc.tuat.ac.jp

Hokkaido University, Social Co-Creation Department, Public Relations Division

E-mail:jp-press (please put @ here) general.hokudai.ac.jp

Related Links(Opens in a new window)

- Tokyo University of Agriculture and Technology Professor Chihiro Fushimi Researcher Profile

- Tokyo University of Agriculture and Technology Professor Chihiro Fushimi Laboratory Website

- Professor Chihiro Fushimi is a member of Department of Applied Physics and Chemical Engineering, Faculty of Engineering, Tokyo University of Agriculture and Technology,