Department of Mechanical Systems Engineering, Graduate School of Engineering, Tokyo University of Agriculture and Technology

Japanese/English

RESEARCH PROJECTS

Volcanic eruption dynamics

"Volcanic eruption-contact with high-speed fluid dynamics and bubble dynamics"

We are conducting research on the dynamics of volcanic eruptions in collaboration with the group of Associate Professor Mie Ichihara of the Earthquake Research Institute, the University of Tokyo.

The photo on the left shows the eruption of Sakurajima, which I happened to meet on a tour of the International Association of Volcanology on July 22, 2013. In Japan, there are more than 100 mountains called active volcanoes, including Sakurajima, that have erupted within the past 10,000 years, which is equivalent to 10% of the world total. Japan's territory occupies only 0.25% of the world's land, so it is a considerable concentration rate.

From a physical point of view, a volcanic eruption can be seen as the process of eruption of foamed magma. This process is a phenomenon closely related to multiphase flow and high-speed flow, which are the specialized fields of our group.

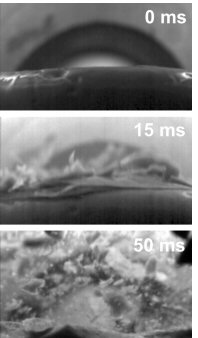

"Crushing of foamed magma due to sudden decompression-laboratory experiment"

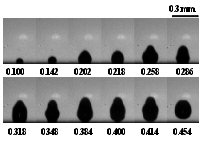

Foaming, which triggers an eruption, occurs as the magma pressure drops or the temperature drops. Our interest is to clarify under what conditions the foamed magma explodes (crushes).

Magma is a fluid with a much higher viscosity than water, but it has the property of "viscoelasticity", which behaves as a solid depending on the time required for deformation. It is thought that when the magma behaves solidly, the gas trapped inside the magma is rapidly released, leading to a large-scale explosion.

Therefore, we have created a device that can pressurize to 100 atm and reduce the pressure to atmospheric pressure at once in less than 1/100 second so that the decompression process that magma receives during a volcanic eruption can be simulated. Using this device, we are conducting a unique laboratory experiment using starch syrup containing oxygen bubbles as a simulated material for foamed magma.

What we have learned through the laboratory experiments and analyzes we have conducted so far is that the solid crushing of magma, which triggers a violent explosion, adds the force necessary for destruction, and the magma itself. It means that the change in the force acting on the force must occur in time to exhibit solid properties (Kameda et al. 2013).

Furthermore, from our experiments, the behavior of magma when the force required for destruction is applied is metastable, and whether or not it becomes an explosive eruption strongly depends on the heterogeneity of foamed magma. It is becoming clear that (Kameda et al. 2017).

Recent (2013-) major papers / explanations and research grants related to this research

- Takeda, S., Ohashi, M., Kuwano, O., Kameda, M. and Ichihara, M. (2020), “Rheological tests of polyurethane foam undergoing vesiculation-deformation-solidification as a magma analogue,” Journal of Volcanology and Geothermal Research, Vol. 393, 106771.

- Ohashi, M., Ichihara, M., Takeda, T., Hirota, K., Sato, S., Kuwano, O., and Kameda, M. (2020), “Formation of tube-pumice structure under pure shear: insights from extension tests of solidifying foam,” Journal of Volcanology and Geothermal Research, Vol. 392, 106772.

- Ichihara, M., and Kameda, M. (2018), “Visualization of Subsurface Magma Fragmentation in Explosive Volcanic Eruption by Analogue Experiments,” Journal of the Visualization Society of Japan, Vol. 38, No. 149, pp. 1-5.

- Kameda, M., Ichihara, M., Maruyama, S., Kurokawa, N., Aoki, Y., Okumura, S. and Uesugi, K. (2017), "Advancement of magma fragmentation by inhomogeneous bubble distribution," Scientific Reports, Vol. 7, 16755.

- Kameda, M., Ichihara, M., Shimanuki, S., Okabe, W., and Shida, T. (2013), "Delayed brittle-like fragmentation of vesicular magma analogue by decompression," Journal of Volcanology and Geothermal Research, Vol. 258, pp. 113-125.

- KAKENHI, JSPS Grant-in-Aid for Scientific Research (A), (2019-2022), "Fracture mechanics of fluid-construction of time evolution model of fracture and examination of flow history dependence," Project Number: 19H00713

- KAKENHI, JSPS Grant-in-Aid for Scientific Research (B), (2016-2018), "Does magma harden or soften with accelerating deformation? - Clarifying brittle fracture process of fluid for application to volcano dynamics," Project Number: 16H04039

- KAKENHI, JSPS Grant-in-Aid for Challenging Exploratory Research, (2014-2015), "Mechanism of fragmentation of inhomogeneous porous viscoelastic liquid in solid/fluid transition regime," Project Number: 26630047

- KAKENHI, JSPS Grant-in-Aid for Challenging Exploratory Research, (2012-2013), "Fragmentation mechanism of vesicular magma in soild/fluid transition resime," Project Number: 24656119

Wind tunnel measurement technology

"Pressure-sensitive paint"

Pressure-sensitive paint (PSP) is applied to a wind tunnel model and optically measures the pressure distribution on the surface. For example, it is not possible to attach a pressure sensor to the entire surface of a wing to measure the pressure applied to it, but pressure-sensitive paint can be used to measure the total surface pressure. Currently, it is mainly used for wind tunnel experiments on aircraft, but its application to automobile models and rotary wings (fans) is also being considered.

We are conducting a wide range of research from the development of the pressure-sensitive paint itself to its application to wind tunnel experiments in collaboration with researchers at the JAXA Wind Tunnel Technology Development Center and the Osaka City University Advanced Research Organization.

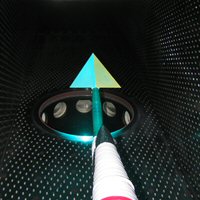

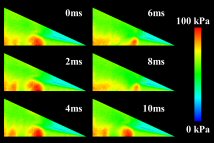

"Unsteady aerodynamic phenomenon measurement with high-speed response pressure-sensitive paint"

This research group is advancing research with a particular focus on the development and application of high-speed response PSPs that target the phenomenon of pressure fluctuations over time.

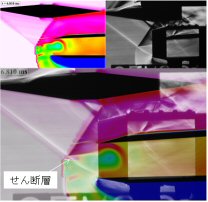

The figure on the right is an example of measurement using anodized aluminum PSP, which is one of the high-speed response PSPs. With the fast response PSP, it is possible to capture the pressure on the surface of the delta wing that changes in 1/1000 second.

Recently, We are also trying high-precision evaluation of temperature / humidity sensitivity required to improve measurement accuracy (Kameda et al. 2015), pressure fluctuation around an object placed in a low-speed flow with smaller amplitude (Noda et al. 2018) and rotary blade (compressor) , Fan) surface pressure distribution measurement (Kitamura et al. 2018).

Recent (2013-) major papers, presentations, and research grants related to this research

- Noda, T., Nakakita, K., Wakahara, M., and Kameda, M. (2018), "Detection of small-amplitude periodic surface pressure fluctuation by pressure-sensitive paint measurements using frequency-domain methods," Experiments in Fluids,Vol. 59, No. 94.

- Kitamura, T., Kameda M., Watanabe, W., Horimoto, K., Akimoto, K. and Akahori, A. (2018) "Mesurement of unsteady pressure field in a turbocharger compressor using pressure-sensitive paint," ASME Turbo Expo 2018: Turbomachinery Technical Conference & Exposition (June 11-15, 2018, Oslo, Norway).

- Nomura, Y., Kameda, M., Nakakita, K., Kato, H., and Koike, S. (2015), "Combined Measurement of Unsteady Pressure and Vorticity Fields of the Flow around a Cylinder by PSP and PIV," Transactions of the Visualization Society of Japan, Vol. 35, pp. 1-6.

- Kameda, M., Yoshida, M., Sekiya, T. and Nakakita, K. (2015), "Humidity effects in the response of a porous pressure-sensitive paint," Sensors and Actuators B: Chemical Vol. 208, pp. 399-405.

- KAKENHI, JSPS Grant-in-Aid for Scientific Research (B), (2019-2021), "Deepening of non-invasive imaging method of pressure / temperature field and development of moving deformed object, high temperature and high pressure field measurement," Project Number: 19H02063

- KAKENHI, JSPS Grant-in-Aid for Scientific Research (B), (2016-2018), "Development of optical pressure measurement techniques for small-amplitude fluctuation, moving body and liquid flow," Project Number: 16H04265

- KAKENHI, JSPS Grant-in-Aid for Scientific Research (B), (2013-2015), "Development of mesurement technique on unsetady surface pressure field on moving bodies using fast-responding pressure-sensitive paints," Project Number: 25289029

Aircraft element technology

"Next-generation supersonic aircraft"

We are conducting research on various elements related to next-generation aircraft in collaboration with researchers at the JAXA Next-Generation Aviation Innovation Hub and Numerical Analysis Unit.

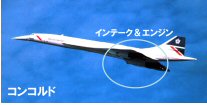

In order to realize the next-generation SST that replaces Concorde, it is necessary to overwhelmingly reduce the environmental load and fuel consumption compared to Concorde. In Japan, JAXA is continuously proceeding with the next-generation SST project, and is currently conducting a "sonic boom reduction method" demonstration test (D-SEND) toward the realization of a "quiet supersonic aircraft ."

"Supersonic engine intake"

The supersonic engine intake is a device for decelerating and compressing the mainstream supersonic speed to suit the engine. Intake is a complex and formidable research subject for fluid dynamics researchers, including internal and external flows, including the flow velocity range from supersonic to subsonic. During the development of Concorde, it is said that it was spent more than half of the wind tunnel experiment intake part on the examination.

In this research group, we paid particular attention to the vibration phenomenon (buzz) of the shock wave system existing in front of the intake, and recently succeeded in constructing a mathematical model of the generation mechanism, and demonstrated the reproducibility by wind tunnel experiments and CFD (Yamamoto et al. 2020).

In addition, we are studying the mechanism (Kojima et al. 2020) and control method of the shock wave vibration (buffet) and noise (TE noise) generated around the wing by the latest mode analysis method.

Recent (2013-) major papers and research grants related to this research

- Kojima, Y., Yeh, C.-A., Taira, K. and Kameda, M. (2020), “Resolvent analysis on the origin of two-dimensional transonic buffet,” Journal of Fluid Mechanics, Vol. 885, R1.

- Yamamoto, J., Kojima, Y., Kameda, M., Watanabe, Y., Hashimoto, A. and Aoyama, T. (2020), “Prediction of the onset of supersonic inlet buzz,” Aerospace Science and Technology, Vol. 96, 105523.

- Kojima, Y., Hashimoto, A., Aoyama, T., and Kameda, M. (2018), "Variation in Spanwise Direction of Transonic Buffet on a Three-dimensional Wing," Journal of the Japan Society for Aeronautical and Space Sciences, Vol. 66, No. 1, pp. 39-45

- KAKENHI, JSPS Challenging Research (Exploratory), (2020-2021), "Development of active wing noise control method based on high-efficiency reduction technology for flow information," Project Number: 20K21043

Basics and applications of gas-liquid two-phase flow

"Bubble mechanics / thermomaterial transport"

The study of investigating the motion of bubbles is called "bubble mechanics". In this research group, We have been conducting basic research to clarify the mechanism of bubble deformation such as bubble generation from small holes as shown in the right figure, bubble dissolution process in bubble jet, in high-viscosity liquid etc., in addition to the research on bubble motion and thermal substance transport due to pressure fluctuations shown in the outline.

Recently, we have broadened the scope to gas-liquid two-phase flow in general, and applied it to biological sensing described below, applied a new visualization measurement method for underwater shock waves in collaboration with Yoshiyuki Tagawa laboratory, and elucidated the liquid film rupture process.

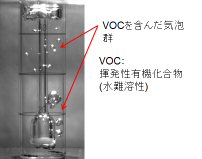

"VOC collection / detection technology that simulates nostrils"

Real-time monitoring of trace volatile organic compounds (VOC) is attracting attention in fields such as anti-terrorism and breath-based disease diagnosis. In particular, it is expected that high-sensitivity biosensors using biological substances will be put into practical use.

Just as important as the development of sensors is the development of sampling technology. In order to use biosensors, it is necessary to establish a method for collecting VOC, which is a poorly water-soluble substance, in water with high efficiency.

In this research group, we have succeeded in to develope a method to overwhelmingly improve the collection rate by adding "odor binding protein (OBP)" to the liquid film in a cylinder such as the nostril (Kida et al. 2015), and to identify odorants in the gas phase using an artificial cell sensor panel (Kida et al. 2018) in collaboration with a research group at Duke University in the United States.

Recent (2013-) major papers and research grants related to this research

- Kida, H., Fukutani, Y., Mainland, J., de March, C., Vihani, A., Li, Y. R., Chi, Q., Liu, L., Kameda, M., Yohda, M. and Matsunami, H. (2018), "Vapor detection and discrimination with a panel of odorant receptors," Nature Communications, Vol. 9, 4556.

- Ishihara, S., Tagawa, Y. and Kameda, M. (2018), "Rupture of an air bubble on the solid surfaces," Journal of Fluid Science and Technology, Vol. 13, Issue 3, JFST0015.

- Kida, H., Tsukada, S., Tagawa, Y., Sato, R. and Kameda, M. (2015), "Effective collection of volatile organic compounds by use of rimming flow with odorant binding proteins in water," Mechanical Engineering Journal Vol. 2, No. 4, p. 15-00244.

- Leading Graduate School Program, "Practical Science Leading Graduate School Supporting Green Clean Food Production," Research Grant, (2014-2016)

- President's discretionary expense, "Overseas dispatch for doctoral students (second semester)," subsidy, (2016)

バナースペース

Kameda Group

Koganei Campus, Tokyo University of Agriculture and Technology

2-24-16, Naka-cho, Koganei, Tokyo, 184-8588, Japan

Professor's office 504 (Bldg. 6)

Laboratory 503, 505 (Bldg. 6),

112 (Bldg. 2)